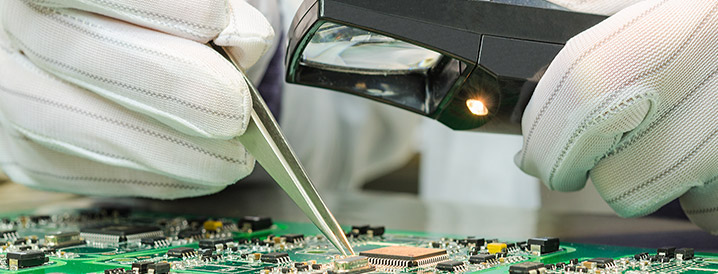

Electronics Quality Control

the products and components that Electronics companies manufacture and assemble are at the center of the exciting, fast-moving, and increasingly complex technologies that touch every aspect of modern life.

In this fast-paced and dynamic market space, Electronics manufacturers are challenged by:

- Increasing global competition

- A need to produce the highest quality products

- A continual need to drive down costs

- Supplies sourced from across globe

As a result of these challenges, quality improvement managers in the Electronics industry need real-time visibility — within plants and across the globe — to proactively:

- Maximize yields

- Drive down costs

- Reduce waste and scrap

- Optimize processes through continuous improvements

- Ensure part and product traceability

What sort of tests and quality checks are essential in Electronics manufacturing?

There are a number of key tests that should be carried out on electronic products. They include functionality checks, reliability testing, safety tests and verification (certification may be required depending upon the product and the country that product will be sold in).

a. Functional checks: it is essential that the product manufactured meets the product specification in order to satisfy the customer’s expectations. The functional checks should be carried out against the product specification document.

b. Reliability testing: this is generally carried out on random samples taken from the production line and subjected to various tests. A common method of testing electronic products is HASS (Highly Accelerated Stress Screening). HASS is implemented at the production stage – production samples are subjected to stress testing beyond the product specification limits.

Early product failures on a new product are often attributed to variability within a manufacturing process. Therefore, identifying these potential production failure modes as early as possible is paramount to the success of a product launch and this is where HASS comes into play.

c. Safety Tests and Certification: different countries have different regulations that must be met in order to sell a product within that country. For most consumer electronic products there would be a minimum requirement from a safety testing point of view. A few examples of the other regulations you should consider are:UL Certification for the US market – Product Safety Testing.

- UL Certification for the US market – Product Safety Testing.

- FCC for the US market – All commercial electronic devices (unintentional radio-frequency radiators) are regulated by the Federal Communications Commission (FCC). This includes almost every product that contains a microprocessor.

- CE Mark for the European Union – The CE-marking is the manufacturer’s statement that his product complies with all relevant CE-marking directives. (And make sure not to put this mark on products to which it does not apply.)

- C-Tick for Australia – The Australian Communications Authority introduced an EMC protection framework requiring EMC compliance for electronic products.

If you are not sure what to do, we can help you identify which regulations you must comply.We can apply our vast knowledge to improve your most pressing Electronics quality control challenges.